Our passion for furniture is obvious in all the little details which we put into the production of each item. A KIAN product is the result of a relationship between human hearts and ordinary pieces of metal, wood, plastic, rattan and fabrics.

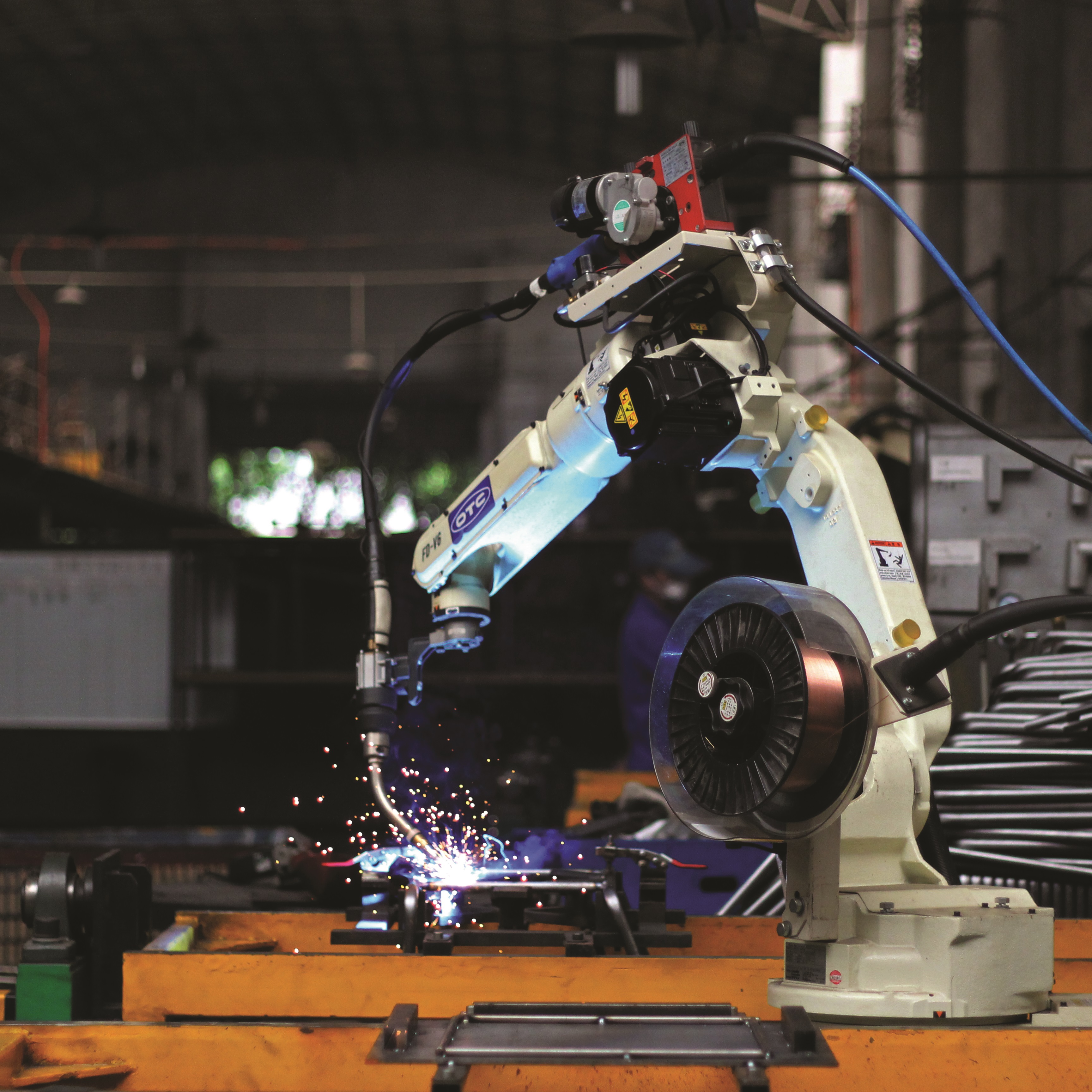

MECHANISED MUSCLE

KIAN’s manufacturing competence is powered by technologically advanced machines, not just by manual labour. We are geared for handling big and small projects. Our factory spans over 400,000 sq ft and houses a plethora of machines with automated processes and mass production capabilities to complete any order on time. But since machines can never match the human drive for excellence, we also have trained operators handling the machines as well as an assembly of skilled craftspeople who painstakingly hand-weave wicker onto frames.

MADE TO MOULD

We do things differently. Using multiple resin injection machines at the same time ensures that huge orders will be fulfilled on time. Not only do we own the moulds, we also make some of them at our factory. KIAN's numerous mould designs produce polypropylene products that are exclusive.

THE WONDER OF WOOD

Naturally decorative, wood has a charm all its own. Its pliability, its range of colours and textures, and even its imperfections, are what makes wood a perennial favourite as a raw material in furniture-making. At KIAN, automated machines and expert hands work together to turn rough wood into items of beauty and functionality.

SHAPING The raw material is precision-cut and auto-shaped by machines into the required furniture components. Any intricate patterns in the design are also carved into the wood at this stage. |

ASSEMBLY & SANDING Each wooden piece is individually fitted into place. The whole unit is sanded to smooth the coarse wood in preparation for the next phase. |

FINISHING The smoothened parts are sprayed, stained,and then cured in hot rooms. Various colour options are available, including the choice of clear coating to highlight the wood grain. |

DELIVERY The final touches are added and the finished product is ready for delivery. KIAN’s wooden furniture adorns places as diverse as F&B establishments, hotels and resorts, education centres, offices, public spaces, and private homes. |

Under One Roof

|

|

|

|

| CNC Plasma Cutting Machine | Robotic Welding | Metalwork | Weaving |

|

|

|

|

| Rotary Moulding | Plastic Injection | Upholstery | Woodwork |

The only way to ensure consistent high quality in both materials and workmanship is to do it ourselves. From the drawing board to the packing of the final product, every stage in the manufacturing of KIAN furniture is carried out within our factory complex. Even the quality and suitability of the raw material for each furniture component – whether wood, metal, rattan or polypropylene – is assessed right at source before it is shaped into the required part. The entire process is minutely monitored and carefully managed each step of the way.